Wind – Transformers

CMC OIL SENSOR

Optimal Oil Management Solution

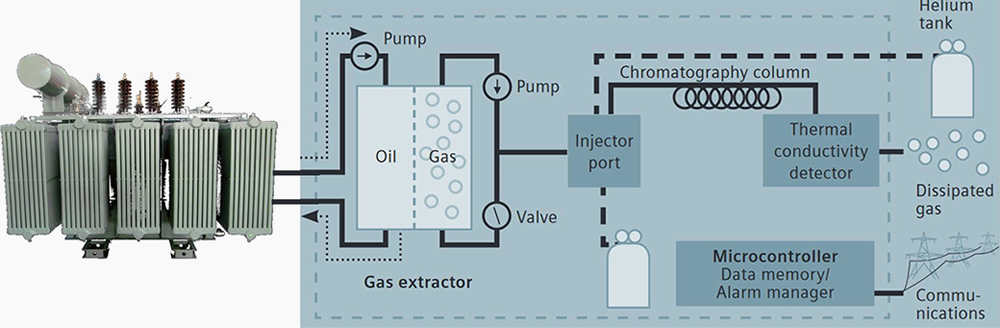

변압기 오일 (절연유라고도 함)은 우수한 전기 절연 특성을 가지며 고온에서 안정한 오일입니다. 변압기 오일은 아크 및 코로나 방전을 방지하고 변압기의 열을 방출 (즉, 냉각제로서 작용)하기 위해 오일 충전 된 전력 변압기에 사용됩니다. 절연 오일의 또 다른 중요한 특성은 대기산소와 셀룰로오스로 만든 종이 단열재사이의 장벽 역할을 하여 산화를 방지합니다.

< Parameter classification of transformer oil >

| Electrical parameters : Dielectric strength, resistivity, dielectric dissipation factor |

Chemical parameters : moisture content, acidity, sludge content |

Physical parameters : Tensile Force, Viscosity, Flash Point, Pour Point |

OilQSens® OQ300 independently measures the electrical conductivity (k), dielectric constant (εr), and temperature (T) of oil to calculate the loss factor (tan δ), breakthrough voltage (dielectric strength), and identify parameter trends to predict replacement intervals. Accurately display warnings and equipment precautions that may occur during operation, such as excessive damage, lubricant acidification, etc.

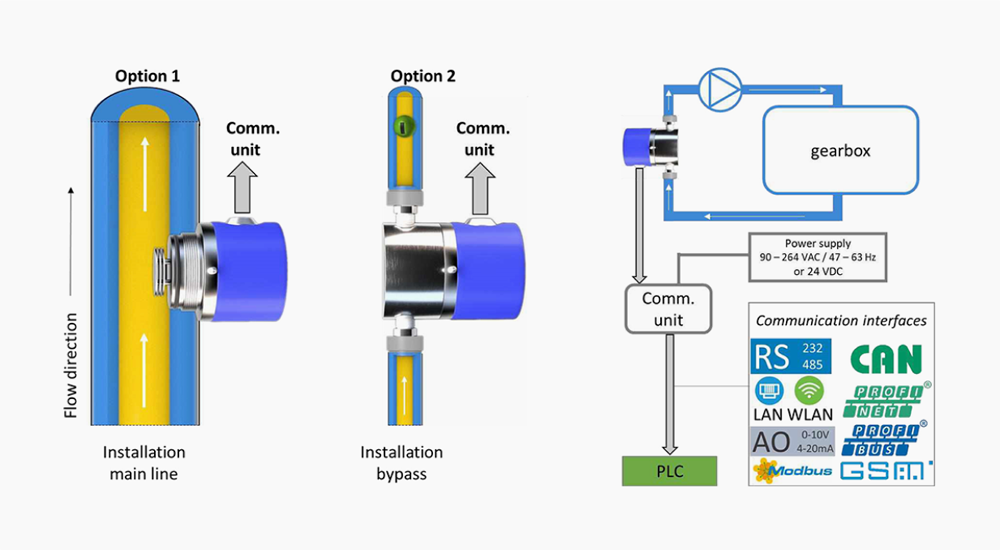

Wind farms use both lubricating oils and lubricating greases. The main role of lubricants is to ensure the reliable operation of mechanical parts. Critical lubrication areas in a wind turbine are in the main gear drive, yaw system gears, main and generator bearings, pitch governor, and nacelle slewing ring. Lubricants must meet numerous performance requirements in the wind industry. Wind farms can be found atop mountains, along coasts, in deserts, and more. Therefore, in addition to longevity issues, lubricants must be able to resist corrosion and oxidation, as well as withstand a variety of environmental conditions, including temperature extremes and moisture. And all of these characteristics must be maintained over the long term. The engine oil in a car is changed after 15,000 to 30,000 kilometers, which corresponds to an oil life of 300 to 600 hours at an average speed of 50 km/h. On the other hand, gear oil in a wind turbine is changed after a maximum of 25,000 to 50,000 hours. The role of lubricants is highly undervalued in the wind energy sector, despite the fact that they have a decisive impact on the performance, efficiency, maintenance requirements and lifetime of equipment. Another aspect to consider in wind farms is that maintenance and repair work must often be performed in unfavorable conditions. This problem will be exacerbated by the large offshore wind farms that will be built in the future. If conditions are too harsh, a faulty part can force the turbine to sit idle for months.

|

|

| OilQSens® OQ3000 |

|||

|

| WearSens® WS3000 |

|||

|