LiquiSonic® measurement systems enable in-line concentration analysis of liquids. Measurement technologies can analyze the components of fluid mixtures and provide information about concentration or density in real time. The sensor is based on the principle of ultrasonic velocity measurement. This makes it virtually maintenance-free and provides reliable measurement values even under challenging measurement conditions.

This makes it very easy to determine the percentage of a particular liquid in a liquid mixture. A variety of sensor variants and options are available for different applications and installation conditions. Let us help you find out how LiquiSonic® measurement systems can solve your measurement tasks.

LiquiSonic® Densitometer

LiquiSonic ® consists of up to four sensors and one controller. The devices are digitally connected, ensuring high drift-free measurement accuracy and interference-free data transmission at distances of up to 1,000 m (3,280 ft). Interruptions due to wiring or extensive recalibration when replacing sensors are now a thing of the past.

Ultrasonic measurement processes produce results of exceptional quality when applied in the field. It can handle extreme processing conditions, such as temperatures between -100°C (-150°F) and +200°C (375°F) and process pressures from several mbar to 500 bar (7,000 PSI). As well as the reliable and maintenance-free nature of LiquiSonic ® and the minimal effort required for installation and operation, it all pays off in the long run, especially when carrying out continuous process improvement.

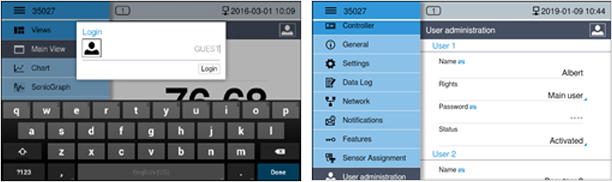

The high-resolution touch screen offers maximum technical comfort and a virtual keyboard including Latin, Asian and Cyrillic characters. Real-time charts show trends and provide quick, clear information about the current process cycle, and menus and display functions are clearly laid out. The user interface is intuitive and easy to use. Password-protected user management and a reliable and comprehensive data memory for all process values and events ensure the traceability, reliability and safety of the system.

Various digital interface options enable simple device integration into any control system. Additionally, the controller can be operated from a PC or tablet via browser connection.

Features

| The latest microprocessor technology | High-resolution TFT touch screen Comfortable even in lighting conditions Operation and optimal visibility |

Front IP65 protection rating |

| Rack mount option or Includes additional field enclosure |

4…20mA I/O, relay contact, Fail-safe contacts, TCP/IP and Fieldbus interface |

Ethernet, serial interface and USB port |

| Measure and event tracking for stable records 2GB SSD data memory |

Multi-channel real-time chart | Includes Latin, Asian and Cyrillic characters. Multilingual user interface and virtual keyboard |

| Different levels of system access Custom passcode for security |

Measurement conditions (e.g. air bubbles) SonicGraph® for optimization (Direct viewing of high-frequency sound wave signals) |

Read data and event storage |

| Read data sheets and reports | Manage diverse product data sets | Products self-made by users Calculate and upload data sets |

| On your PC or tablet Controller via browser Securely remote control |

||

Features

01

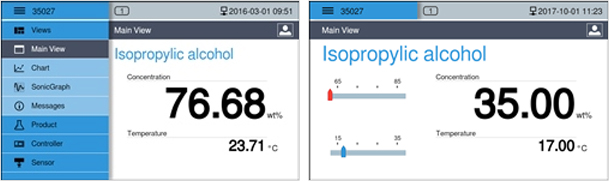

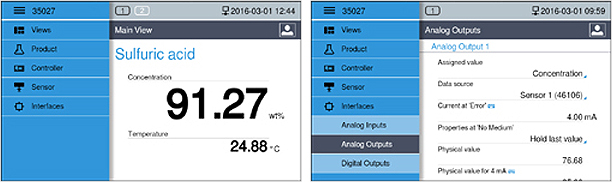

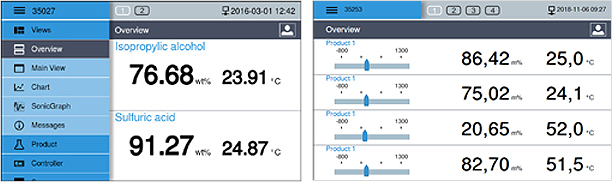

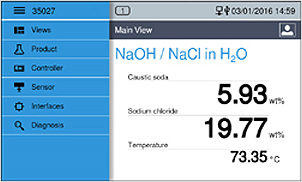

Clear display layout

–

The controller’s main view provides a quick overview of the current product, measured values and liquid temperature at the measuring point.

The limit value display in the left screen area allows you to quickly recognize deviations from the desired measuring range.

When the limit is exceeded, the pin showing the current value turns red.

02

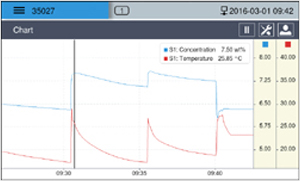

View chart

–

Trend charts provide useful information and allow optimal process monitoring.

03

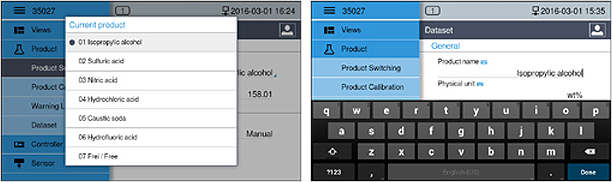

Product Data Set Management

–

The controller manages data sets of up to 32 products or optionally up to 99 products.

You can select products through specific menus. You can change the product name using the virtual keyboard.

04

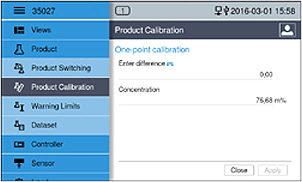

Caliber measurement

–

Concentration calculations can be adjusted to achieve optimal process results.

05

User-friendly menu

–

The controller has many parameters and useful functions. Parameters are structured in a parameter tree.

06

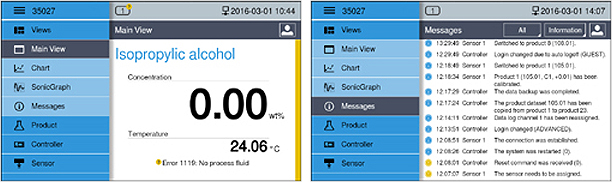

Event logbook and alarm messages

–

The device has an automatic self-check function. All alarm messages are clearly displayed on the display and stored in the event logbook.

The logbook appears on the display and can be transferred using the USB port.

For example, an event logbook tracks which users have which products calibrated to which values.

07

User Management

–

System security is very important. The controller provides comfortable user management.

You can define multiple users with different access rights.

This user management ensures that only specific users can calibrate the device.

08

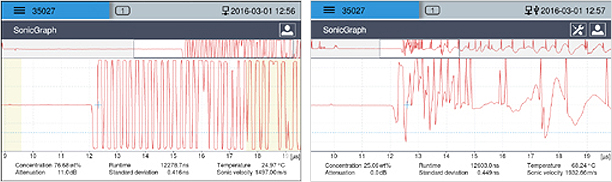

SonicGraph®

–

The sensor option SonicGraph® allows you to visualize the raw ultrasound signal.

This function is very useful for optimizing measurement conditions, for example those affected by air bubbles.

09

Multilingual

–

The controller can operate in several languages, and text input is possible in Latin, Asian and Cyrillic alphabets.

Available languages: German, English, French, Spanish, Portuguese, Russian, Chinese, Japanese, Polish

10

Multiple measurement points

–

The controller 30 includes the possibility to manage up to four sensors.

Values from multiple sensors are displayed in 2- or 4-sensor views.

11

Multi-component display

–

The controller 40 calculates and displays two different concentrations in a ternary liquid.