AMETEK Brookfield FAST systems have a rugged design with non-moving parts. Designed to perform daily, maintenance-free, under the extreme demands of printing, coating and gluing operations. Using a high-frequency micro-rotating core that is immune to press vibration, this worry-free system can measure and control the viscosity of inks, coatings and adhesives from start to finish. Operators are free to handle other press issues.

FEATURES & BENEFITS

| Unique Micro Rotation Sensor | No moving parts, no maintenance | Not affected by external vibration |

| Flexible vertical or horizontal installation | Actual temperature reading up to 120°C | Maintain accurate color throughout the process |

| Compact height 8.5 inches | ||

| Worldwide Support | ||

Specification

FAST/MXTS SENSOR SPECIFICATIONS

| Measurement type | Torsional vibration probe |

| Measurement range | NIST traceable Newtonian fluid measured at 25°C. Use 1 to 3,000 (option 12,000) cSt |

| Process Connection | ¾” standard (1, 2½” tri clamp or 3A design, optional) |

| Repeatability | ±1.0% of reading |

| Wet Surface | 316L stainless steel |

| Sensor O-ring | Isolast for Viton probes for chamber housing (EDPM or Kalrez®, optional) |

| Temperature (fluid) | -4°F to 248°F (-20°C to 120°C) |

| Pressure range | Vacuum up to 200 psig |

FMXTS TRANSMITTER SPECIFICATIONS

| Viscosity range (cSt) (field selection possible) |

0 to 10, 0 to 50, 0 to 100, 0 to 250, 0 to 500, 0 to 1000, 0 to 1500, 0 to 2000, 0 to 12500 |

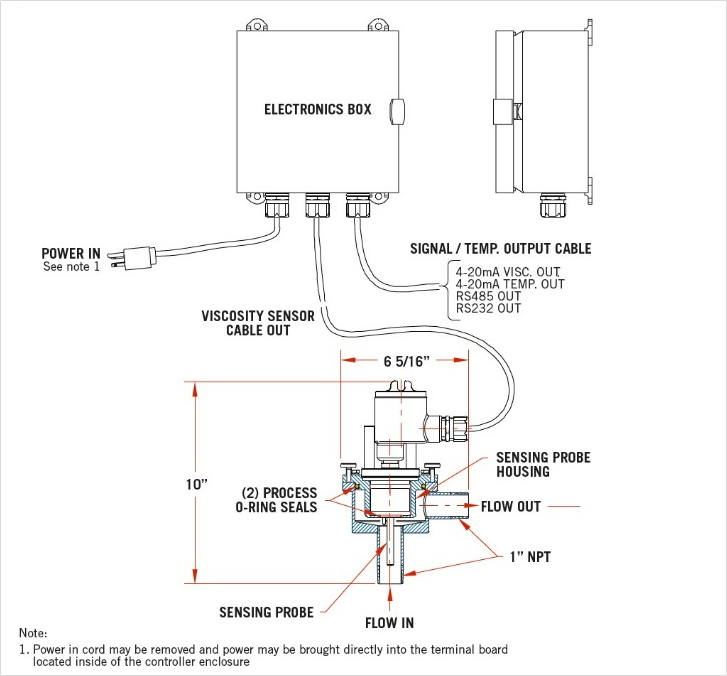

| Analog output (2) | 4-20mA (non-isolated) CH1 = Viscosity / CH2 = Temperature |

| Serial Port (2) | Port 1 = RS232, simple, read only Port 2 = ½ Dual RS485, Modbus RTU driver |

| Electronics Packaging | Wall mount, NEMA-4 (IP65); 8” x 8” x 6” (203 x 203 x 152 mm), 32°F to 104°F (0°C to 40°C) |

| Interconnect Cable | 25 feet (7.6 m) standard Options: 50 feet (15.2 m), 75 feet (22.8 m), and 100 feet (30.4 m) |

| Power voltage | 18-30VDC or 115VAC/60Hz or 230VAC/50Hz (±10% max), power consumption <1 amp |

Typical Installation : AST-100TSY (115 or 230V)