FLUXUS uses ultrasonic waves to measure flow non-intrusively. Clamp-on sensors are simply installed on the outer wall of the pipe. Therefore, there is no wear or damage caused by the measurement object in the pipe, and there is no risk of liquid or gas leakage or pressure loss. And above all, it has the advantage of being able to be installed and maintained while the plant is running without stopping the process.

FLUXUS Clamp-On Ultrasound System

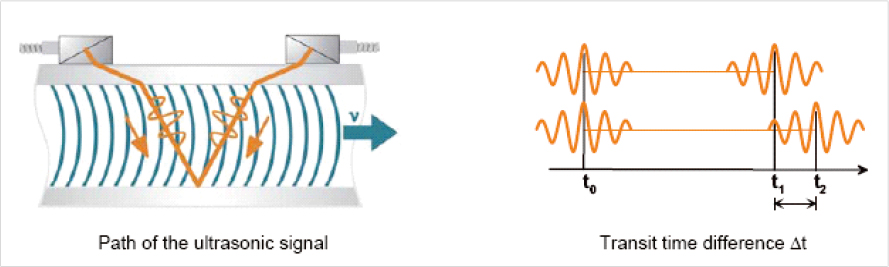

FLUXUS clamp-on ultrasonic systems measure volumetric flow by time-of-delivery methods. Since the ultrasonic signal propagating inside the pipe is transmitted by the fluid flowing inside the pipe, there is a time difference between when it propagates in the same direction as the fluid flow and when it propagates in the opposite direction to the fluid flow. This time difference can be measured very accurately, and the measuring transmitter calculates the volumetric flow value based on the parameters of the pipe structure and the physical properties of the workpiece stored in the database.

Measurement principle

| Almost all liquids and Capable of measuring gaseous media |

Significant amounts of solids and gases or Including wet gas (LVF <5%) Measurement is also possible |

The non-invasive acoustic measurement method has no inertia and Very high measurement dynamics in both directions |

| Transmission time difference measurement and density measurement When combined, it measures the mass flow rate of the liquid |

Transmission time difference measurement and pressure measurement When combined, measures the standard volumetric flow rate of gases |

Clamp-on technology Provides maximum flexibility |

| FLUXUS’ sophisticated electronics Guarantee the highest level of reliability |

Consisting of a transmitter and an ultrasonic sensor The measurement system is tailored to the specific requirements given. Can be adjusted to optimal condition |

Apply to general applications Provides a wide range of product lines |

| Applied to a wide range of fields | To an area with the potential for ignition and explosion. Explosion-proof models available for installation |

The ultrasonic sensor is For flow measurement of battery slurry Optimized 2MHz type |

| Ultrasonic sensors have completed field verification and are widely used in battery cathode production lines | ||

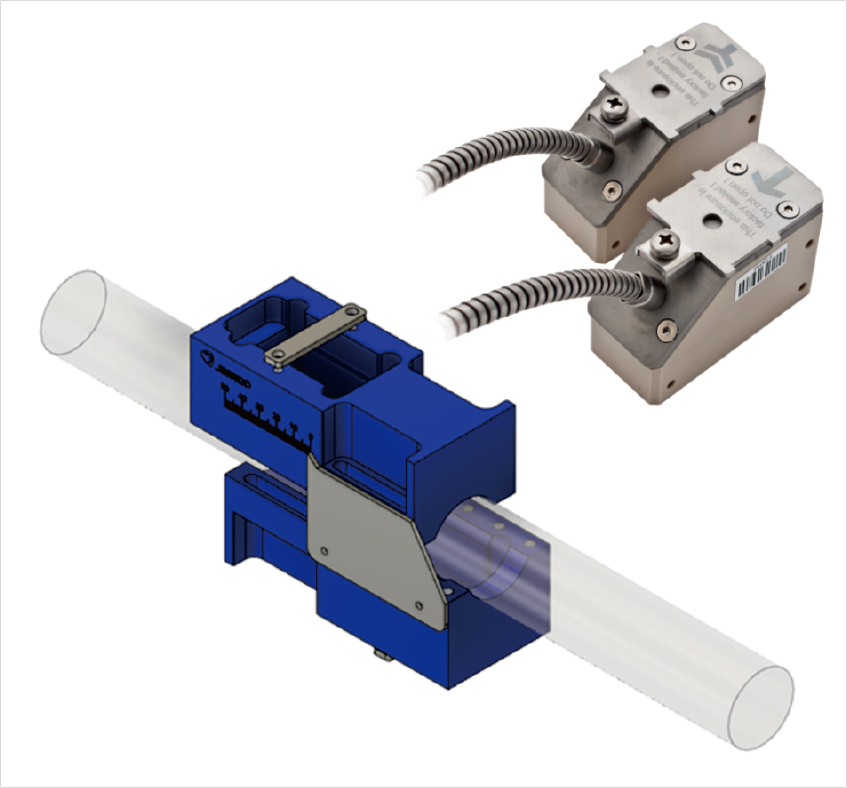

Mounting Tool

The mounting tool exclusively for ultrasonic sensors manufactured by Jinwoo Hi-Tech is available in 1.0S and 1.5S specifications.

It is specially manufactured and supplied for the battery production process, which requires frequent piping cleaning with precise spacing and easy attachment and detachment.

Specification

Fluid measurement

| Flow rate | 0.01 m/s to 25 m/s |

| Precision | ±1.0% of reading ±0.005 m/s (±0.5% of reading ±0.005 m/s) |

| Reproducibility | 0.15% of reading ±0.005 m/s |

| Pipe size | 6 mm to 6,500 mm (inner diameter) |

Operating conditions

| Process fluid temperature | -40 °C to 240 °C (max. -200 °C ~ 600 °C) |

| Ambient temperature | -10 °C to 60 °C |

| Protection level | IP66 / NEMA 4P, FM Class I, ATEX / IECEx Zone 2 |