| Small form factor for simple installation | In Newtonian and non-Newtonian fluids Stable, repeatable measurements in real time |

Wide range of sensors with one sensor Track viscosity changes |

| All metal (316L stainless steel) construction | Not affected at all by installation conditions | Built-in fluid temperature measurement |

| 7500psi (500bar) and Operates at 575°F (300°C) |

Threads, flanges and sanitary process fittings | Easy cleaning for expansion; No maintenance or reconfiguration |

Specification

Fluid measurement

| Viscosity range | 3 to 3,000 cP (standard) 0.5 ~ 50,000 + cP (Available) |

| Viscosity accuracy | Offers better than 1% accuracy of 5% of reading (typical) |

| Reproducibility | Better than 1% of reading |

| Temperature | Pt1000 (DIN EN 60751 class B) |

Operating conditions

| Process fluid temperature | -40 up to 300°C (575°F) |

| Ambient temperature | -40 up to 150°C |

| Pressure range | Up to 7,500 psi (500 bar) |

How it works

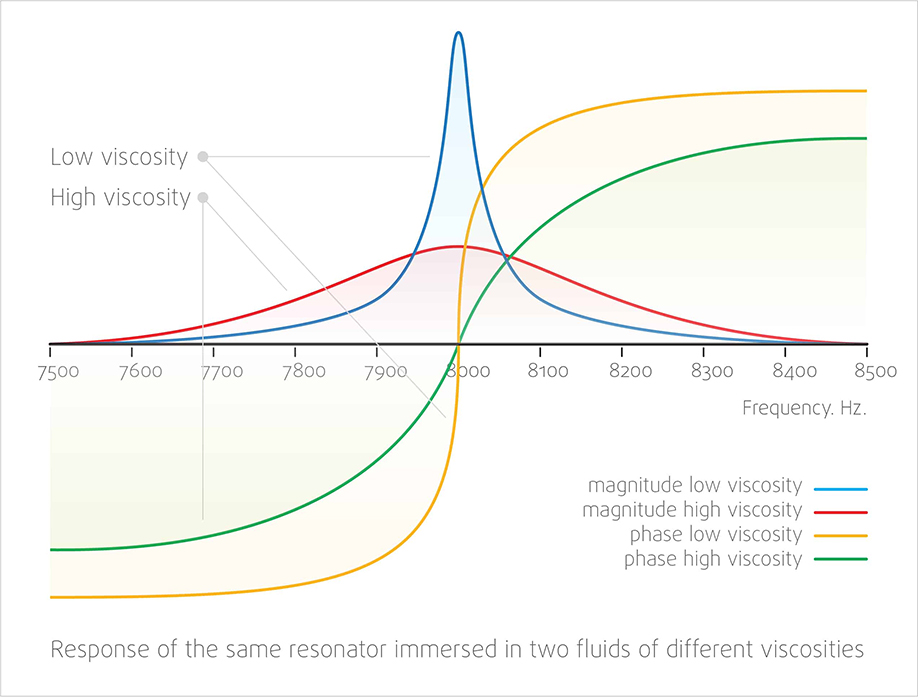

The Rheonics SRV fluid viscometer measures viscosity via a torsional resonator. A torsional resonator has one end immersed in the fluid under test. The higher the viscosity of the fluid, the higher the mechanical damping of the resonator. By measuring the attenuation, the product of viscosity and density can be calculated using Rheonics’ proprietary algorithm.

The resonator is excited and detected through an electromagnetic transducer mounted on the sensor body. Damping is measured with Rheonics’ patented sensing and evaluation electronics, which achieve stable, high accuracy and repeatable readings based on Rheonics’ proven gated phase-locked loop technology.