Quality monitoring of gearboxes, engines, turbines, bearings and hydraulic systems: conductivity, dielectric r and temperature T can be measured to check wind turbine wear, additive consumption and oxidation in oil.</p >

Initial change detection

For online oil condition monitoring, early indication of oil change leads to optimal loading and timely preventive maintenance. The result is significant savings in costs, downtime and work time. Changes in oil are one of the precursors to particle shear and pitting of bearing raceways, and early detection can warn of potential hazards. Early detection can warn of potential damage conditions before damage occurs. WearSens® works from day 1 and is discovered before other technology limitations take effect. Tests have shown that WearSens® can detect oil deterioration, but standard laboratory analysis still reports the oil as good. Vibration and particle monitoring detect only after damage is complete.

A completely new approach

Conceived, developed and manufactured in Germany, WearSens® represents a completely new approach to oil condition monitoring in a variety of applications. For the first time, oil changes can be detected continuously and accurately online. As a result, you can expect optimized loading, reduced wear and savings.

| Conductivity, permittivity and temperature are measured with high precision | Both conductivity and permittivity depend on temperature. Depends on contaminants Temperature compensation is unknown |

Neural network-like self-adaptive temperature compensation function |

| Conductivity per meter Measured in picosiemens (m/Ps) |

Formation of compounds from broken oil molecules, Indicates the presence of particulates and consumption of additives |

Comparison possible at any time through temperature compensation values |

| Relative permittivity is a measure of dielectric constant | The dielectric constant varies depending on the additive used. Decrease, but increase as all additives are consumed |

When taken together with the conductivity value, the oil A clear picture of change emerges |

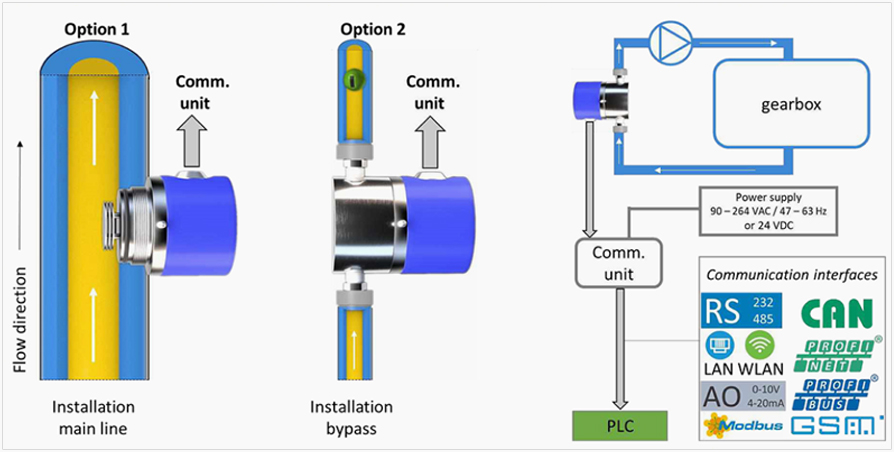

| Measurements are made on LAN, WLAN or Transmission via serial interface |

||

Specification

Fluid measurement

| Conductivity | 0.1 to 100,000 pS/m (max. 2,000,000 pS/m) |

| Relative permittivity | 1 to 5 |

| Sensitivity | 0.1 pS/m |

| Relative permittivity | 1 x 10 ^-6 |

Operating conditions

| Oil pressure | 60 bar at 20 °C (870 psig 68 °F) |

| Oil temperature | -10 to 70 °C (max. -40 to 150 °C) |

| Operating Temperature | -20 to 70 °C |