| In-Process & Laboratory Viscometer | Full Set of Real-Time Rheology Data | Improve Product Quality |

| Forecast Production and Optimize Supply | Smart Manufacturing | Optimize Capacity and Resource Utilization |

| Operable in ATEX Zone 2 |

Specification

Measurement

| Viscosity Range | 100~50,000 mPa·s at 10 s-1

10~5,000 mPa·s at 100 s-1 1~500 mPa·s at 1000 s-1 |

| Precision / Repeatability | Viscometry: ±2% |

| Temperature Range | 20 ~ 40 ±0.3℃ |

| Data Output | Time per measurement : 1 ~ 3 min

Viscometry : Flow curve, 1 ~ 3 point of viscosity vs. shear rate |

Hardware

| Dimensions | Cabinet : 300 x 300 x 220 [mm] (H x W x D)

Including external components : 415 x 330 x 280 [mm] (H x W x D) |

| Weight | Max. 15kg |

| Materials | Cabinet : Stainless Steel, Aluminium

Contact with sample : Stainless Steel 316, PTFE, Nylon 12, Borosilicate glass & PEEK |

| Protection Class | IP65 (IP66 with Cabinet) |

In-Line Rheometer

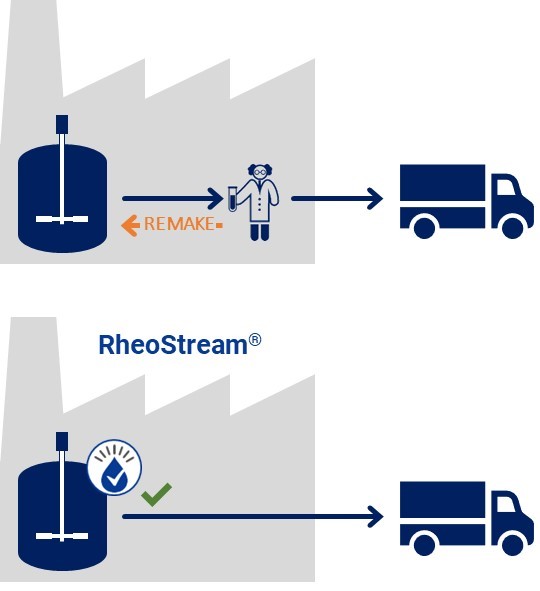

RheoStream is a rheometer for real time in-process measurement of viscosity, shear thinning and apparent yield stress in viscous non-Newtonian liquids.

● Inline viscometers providing real-time data on viscosity

● Manual in-plant rheometers providing empirical rheology values

● Laboratory rheometers providing a full set of rheology data

The measures provided by RheoStream®

RheoStream measures viscosity, shear-thinning, and apparent yield stress in non-Newtonian liquids.

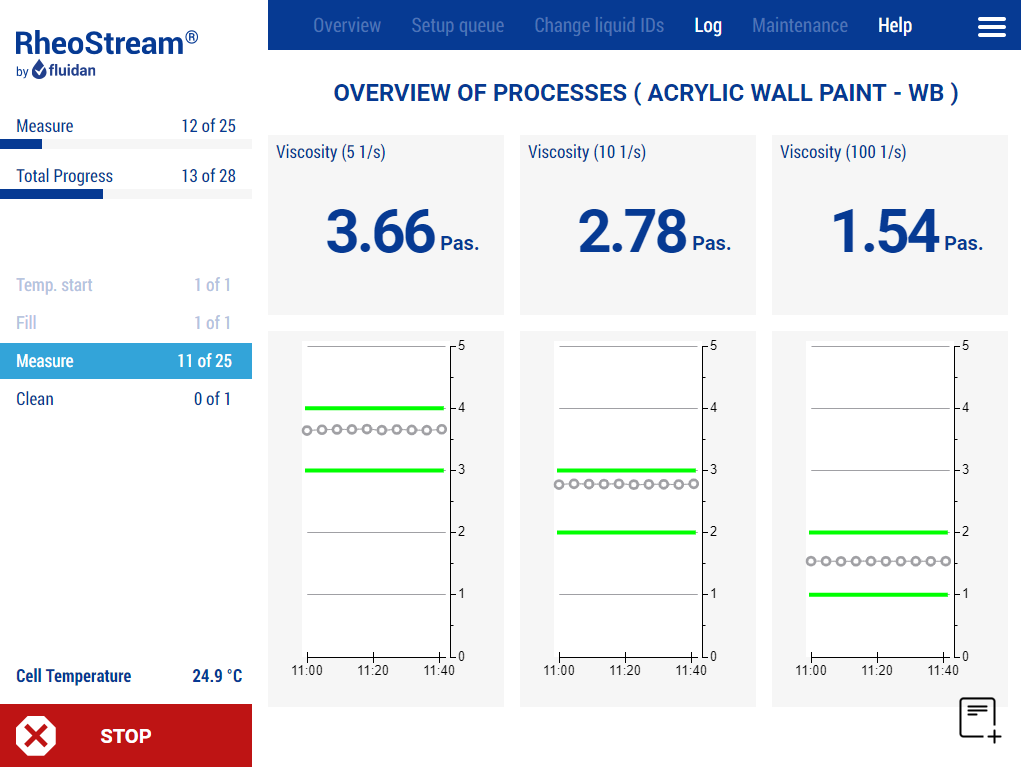

The output data from RheoStream :

● Reports viscosity (or shear stress) at 3 pre-selected shear rates

● Optionally, calculates and report alternative viscosity model parameters (Bingham, Herschel-Bulkley, Cassons)

● Displays the temperature at which the measurement takes place.

Customized Liquid Measurement with RheoStream®

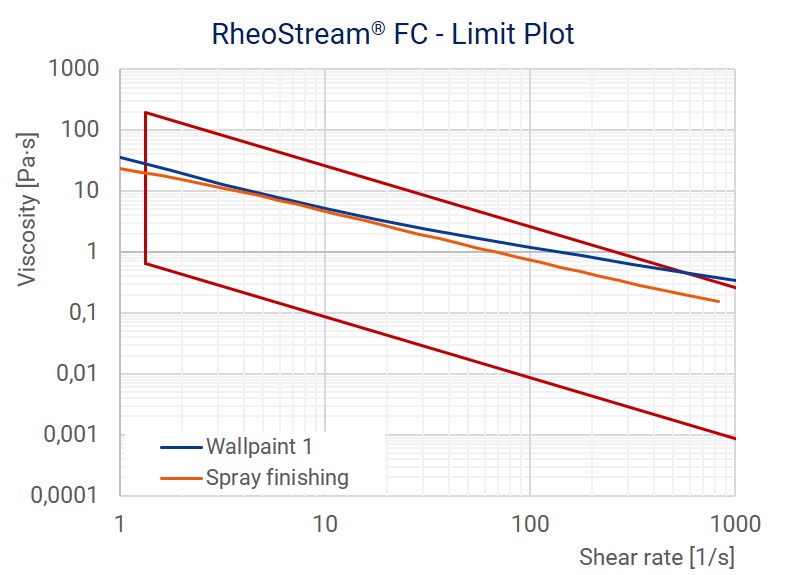

RheoStream works for liquids with particles smaller than 200µm(Max. 500μm). The sample coming in may be 10-60°C, and is cooled/heated to the desired measuring temperature. RheoStream covers a shear rate range of 1.5-1000 [1/s]. The viscosity range depends on the shear rate of the measurement

“Application area” indicated in the picture below :

● Above the upper solid red line, the samples are too thick, limited by the internal parts

● Below the lower red line, the samples are too thin, reaching the signal/noise limit of the instruments

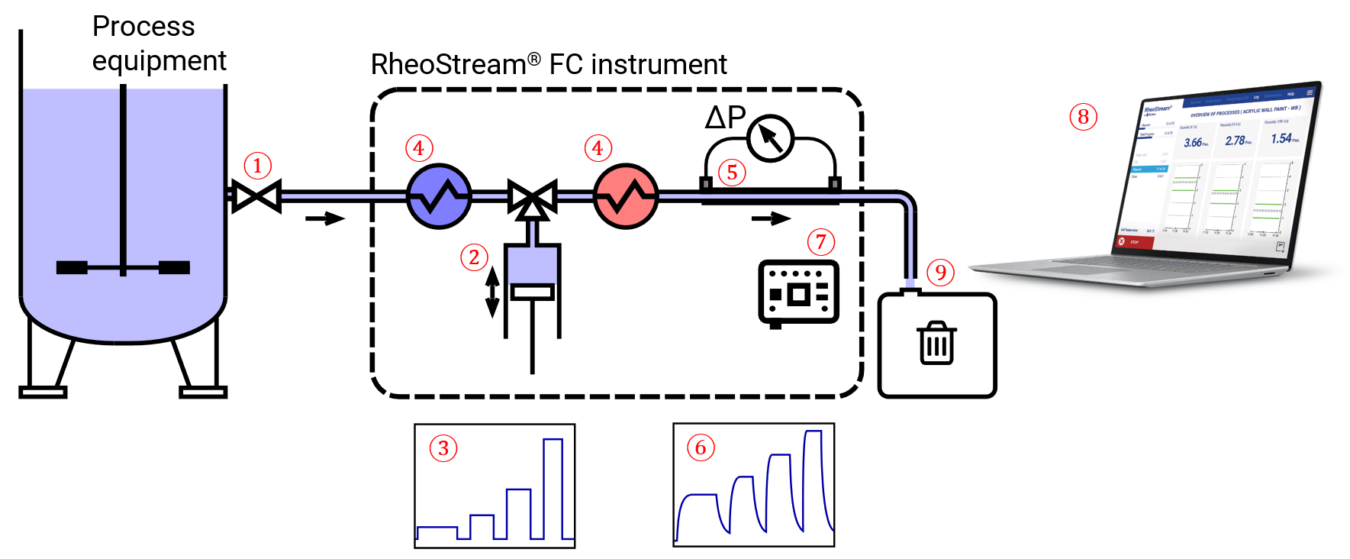

How RheoStream® Works

① A sample is drawn from process equipment

② The syringe pump controls flow rates in pulses ③

④ A preheater/cooler ensures a steady temperature of the measurement

⑤ The liquid flows through a thin tube (capillary)

⑥ A pressure difference (ΔP) is measured for each pulse

⑦ The instrument computer converts pressure signals into viscosity values

⑧ Displays results on the user interface

⑨ Spent sample is collected as waste