3-Axis CNC Motor and Video Edge Detector(VED), take 2D Profile measurements across a wide range of industries, from Automotive to Aerospace, Medical, Batter, and more.

Specification

| Quadra-Check 5300: 3 Axis Windows™-based metrology software | 3 Axis CNC Drives | Optimet non-contact single laser range sensor with one lens |

| Manual & Automatic mode for user-directed measurements or fully automated system configuration | ||

ACU-GAGE

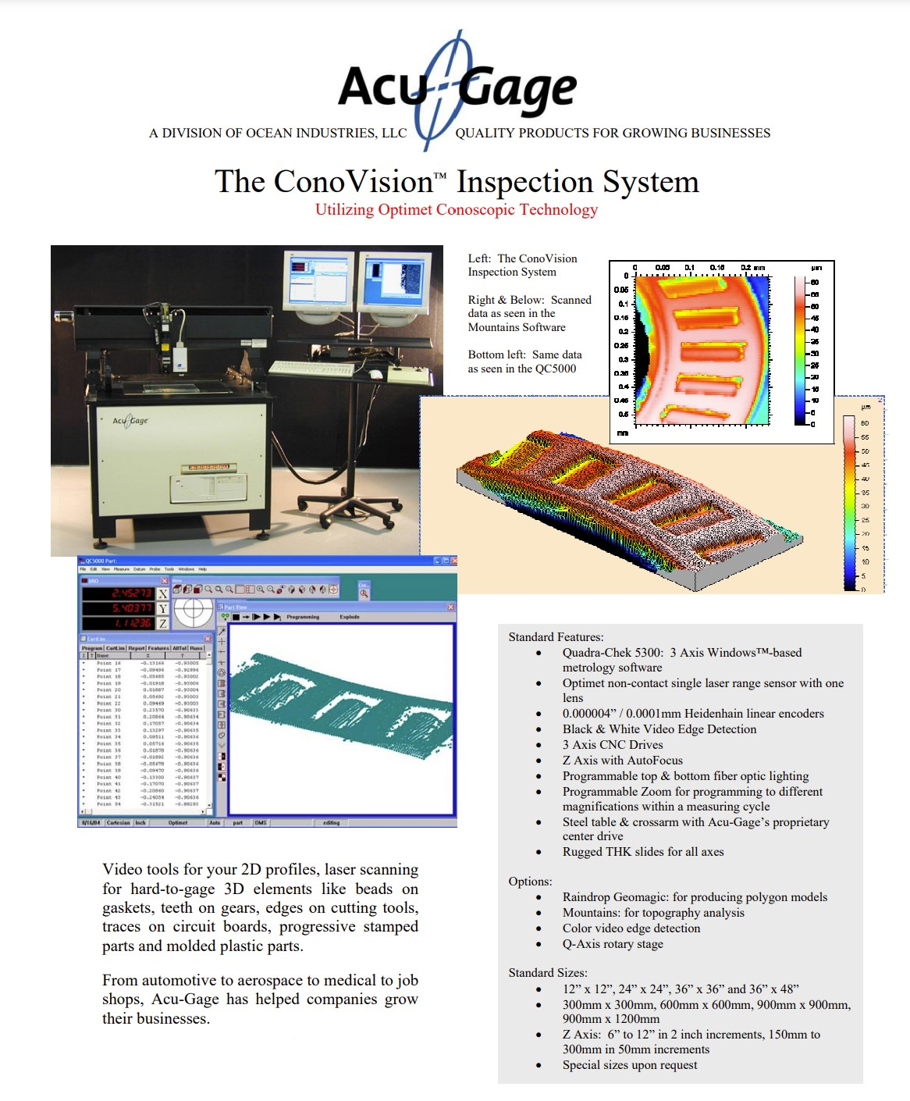

The Acu-Gage ConoVision model offers exacting precision, high point volume laser measurement for end users seeking accuracy for their 3-d measuring needs. Unlike other laser measuring devices that incorporate a lower resolution triangulation laser to their systems, Acu-Gage utilizes a patented thru-the-lens laser for high resolution 3-d laser scanning. The Optimet dynamic laser measurement sensor scans at a rate of 3,500 points per second, generating a point cloud much denser than that from any conventional touch probe CMM. More points yields a truer definition of the measured part.

Our customers include military operations, fuel cell manufacturers, semi-conductor providers, and high accuracy medical applications. ConoVisions reverse engineer cutting tools used in fabricating jet engine turbine blades, compare high volume 3-d point clouds to CAD files in molded plastic parts, and scan special paper weaves used in manufacturing passports and currency. Where 3-d accuracy is critical on intricate and complex parts, the Acu-Gage ConoVision offers a valuable solution. Touch probes can be integrated to accommodate blind features.

ConoVision Multi-Sensor Components

| Video probe with Fiberoptic Ringlight | Programmable Zoom | Joysticks | CNC Motor |

| Video / Laser | Laser Power | VED Calibration Glass |